Oxidization– The issue occurs whenever oxygen finds itself into the reflow oven causing a quick degradation of matter. Although there are many different issues that can appear, we review some of them to illustrate some occasional results. Reflow soldering requires extensive consideration of the key factors. Reflow Soldering Common Problems and Their Causes Here are some reasons why to choose PCBONLINE: Working with them, you can receive assemblies exceeding your expectations. Their reflow soldering ovens cover all the customer’s requirements. They are advanced printed circuit board assemblers with rich experience.

If you are looking for a reliable PCB assembler that is familiar with reflow soldering, PCB Assemblers Recommendations - Where You Can Expect Perfect Reflow Soldering You can turn toĪn advanced PCB assembler. However, if you are not determined to build yourself an assembly line, it’s not recommended to buy such an expensive reflow soldering oven. When you know the line speed, it is easy to determine what chamber and heated length to use in order to meet your workflow requirements.

Solder reflow temperatures how to#

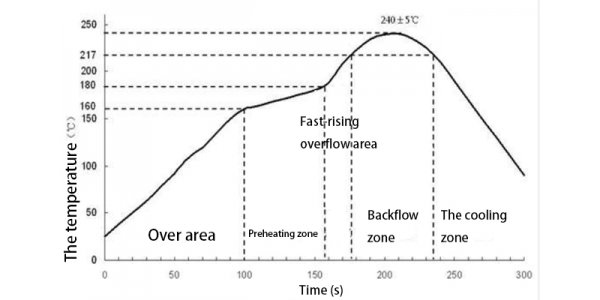

Here is how to calculate the production line speed: The oven has to be a suitable size to seamlessly handle the production rate of the pick and place equipment. There are many different types of reflow soldering machines available, specializing in a different design, line of speed, material, and printed circuit boards. The preferred approach to reflow soldering is with an industrial convection oven to SMT components to a PCB. While those simple PCB assembler’s ovens have only 8 temperature zones, and they can’t solder lead-free boards. PCBONLINE use a reflow soldering oven with 10 temperature zones. The typical reflow soldering oven has different temperature zones and the temperature occasionally increases according to a pre-set curve that has to be adjusted as per the assembly aspects and temperature requirements.Īdvanced printed circuit board assemblers like Lead-free soldering, the reflow temperature should reach Sn/Pb solders, the melting point temperature typically peaks aroundĢ15☌ to 245☌with around 20-60 seconds above 183 degrees. The PCB industry has many different reflowing components requiring certain temperatures. Temperature Requirements for Reflow Soldering The recommendation here is to keep the rate of cooling above 3 degrees a second. Make sure to never cool down the assembly too rapidly as it could lead to malfunctions. Cooling- It is not healthy to heat the assembly fast, here would be the same.If the reflow profile provides insufficient heat, it will result in bad solder joints which is one of the most common defects. On the other hand, it is important for the temperature to be high enough in order to achieve the desired results. The time is about 30 to 60 seconds and it should not exceed to avoid the creation of brittle solder joints.Īnother thing that you should know is that the peak of the temperature has to be strictly controlled as many of the components could fail if they are exposed to excessive heat. The time in which the solder is held above the melting point temperature (time above liquidus) is important to ensure that the "wetting" occurs between the printed board and the components. Reflow- In this general stage, the temperature in the oven is increased above the melting point of the solder paste, forming it into liquid.

The soaks last no more than 60 to 120 seconds, depending on the type of assembly. Soak- This is the part of the project in which it ensured that the components have reached the required temperature before entering the next reflow stage.Fast heating could cause component defects such as Proheat- During this phase of the process the printed circuit board, components and solder are heated to a specific dwell or soak temperature, with the main aspect, which is not to be heated too quickly (usually no more than +2 degrees a second).In order to create an appropriate reflow profile, thermocouples are connected to a simple assembly (often using high-temperature solder), in different locations to measure the range of temperatures across the printed circuit board. The process is focusing on creating acceptable solder joints by pre-heated components, which provides the opportunity to melt the solder without causing damage by overheating. Reflow soldering is the most popular and widely used method of connecting surface mount technology (SMT) components to a Stick around to review in-depth and learn everything you are looking for. Air or nitrogen is heated to a high enough temperature and then blown to the assembly, and the solder on both sides of the component melts and bonds to the motherboard.Ĭritical stepsin reflow soldering, and common After a solder paste is used to attach thousands of tinyĮlectrical components to their contact pads, the entire assembly is sent to a controlled heat.

0 kommentar(er)

0 kommentar(er)